Plastics with a Purpose

How the University of Houston is Reshaping

the Future of Plastics

Plastics with a Purpose

How the University of Houston is Reshaping

the Future of Plastics

Story by India Ogazi | Design by Marcus Allen

Plastics have become mainstays in the fabric of modern life, offering invaluable benefits to society in areas such as food preservation, water filtration and health care. Yet, the ubiquitous nature of plastics has resulted in a global crisis, with staggering amounts ending up as pollution, particularly in our landfills and oceans. At the University of Houston, an effort is underway to confront this issue head-on, from faculty researchers who are revolutionizing plastic manufacturing to students devising innovative solutions to curb plastic pollution.

Revolutionizing Plastic Recycling: A Chemical Approach

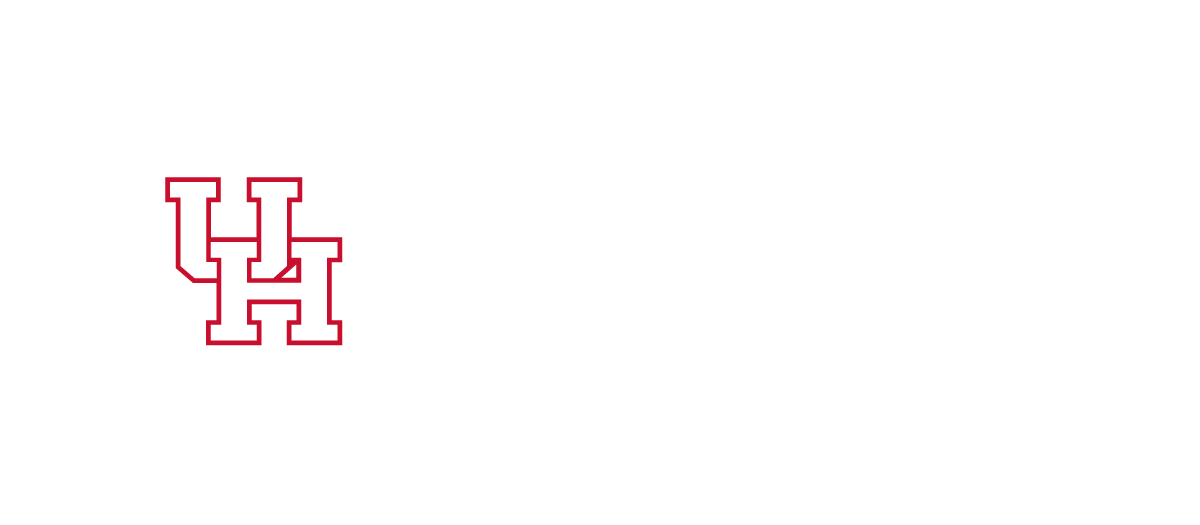

Professor Megan Robertson with Justin Smith

Professor Megan Robertson with Justin Smith

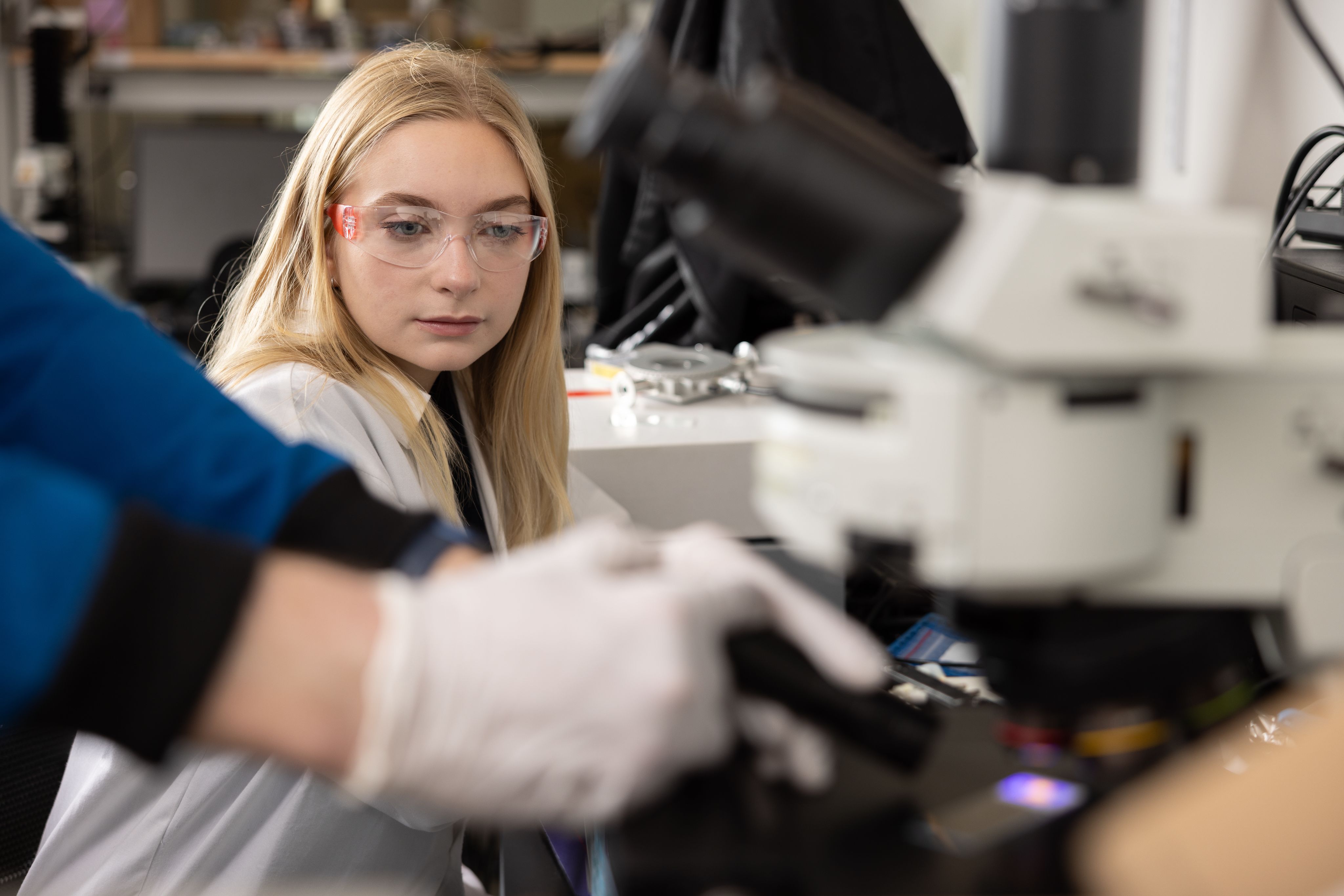

Armed with a $4 million grant from the Welch Foundation, Professor Megan Robertson and her research collaborators at the UH Cullen College of Engineering and UH College of Natural Sciences and Mathematics are leading the charge by developing new chemical paradigms that will revolutionize our approach to recycling.

Robertson and her team of six faculty members and more than 20 post-doctoral researchers are pursuing three distinct efforts aimed at enhancing plastic recycling practices without losing the very properties that make plastics so beneficial.

“We know there are numerous benefits of plastics and what they do for society, but we need to address their limitations in a way that’s better for the environment,” Robertson said. In particular, the team is focusing on a class of plastics called polyolefins, such as polyethylene and polypropylene, which represent more than 60% of all U.S. plastics but have dismal recycling rates.

The first goal is to tackle the issue of compatibilization. As Robertson explained, the current plastic recycling process involves heating the material until it becomes liquid, then reforming and cooling it in pellets ready for the manufacturing pipeline. But first, recycling centers must sort the plastics based on molecular composition. Otherwise, the different plastics won’t mix unless a stabilizing agent is added. The UH research team has identified polymer molecules that can be added to the plastic waste as needed, allowing diverse plastics to be recycled together without the need for extensive sorting—a game-changer for recycling facilities burdened by the complexity of plastic waste streams.

“Having modular compatibilizers that can be mixed and matched as needed to the types of plastics coming into the recycling facility would keep the process moving without the extensive sorting that is required currently,” she said.

“We know there are numerous benefits of plastics and what they do for society, but we need to address their limitations in a way that’s better for the environment.”

- Professor Megan Robertson

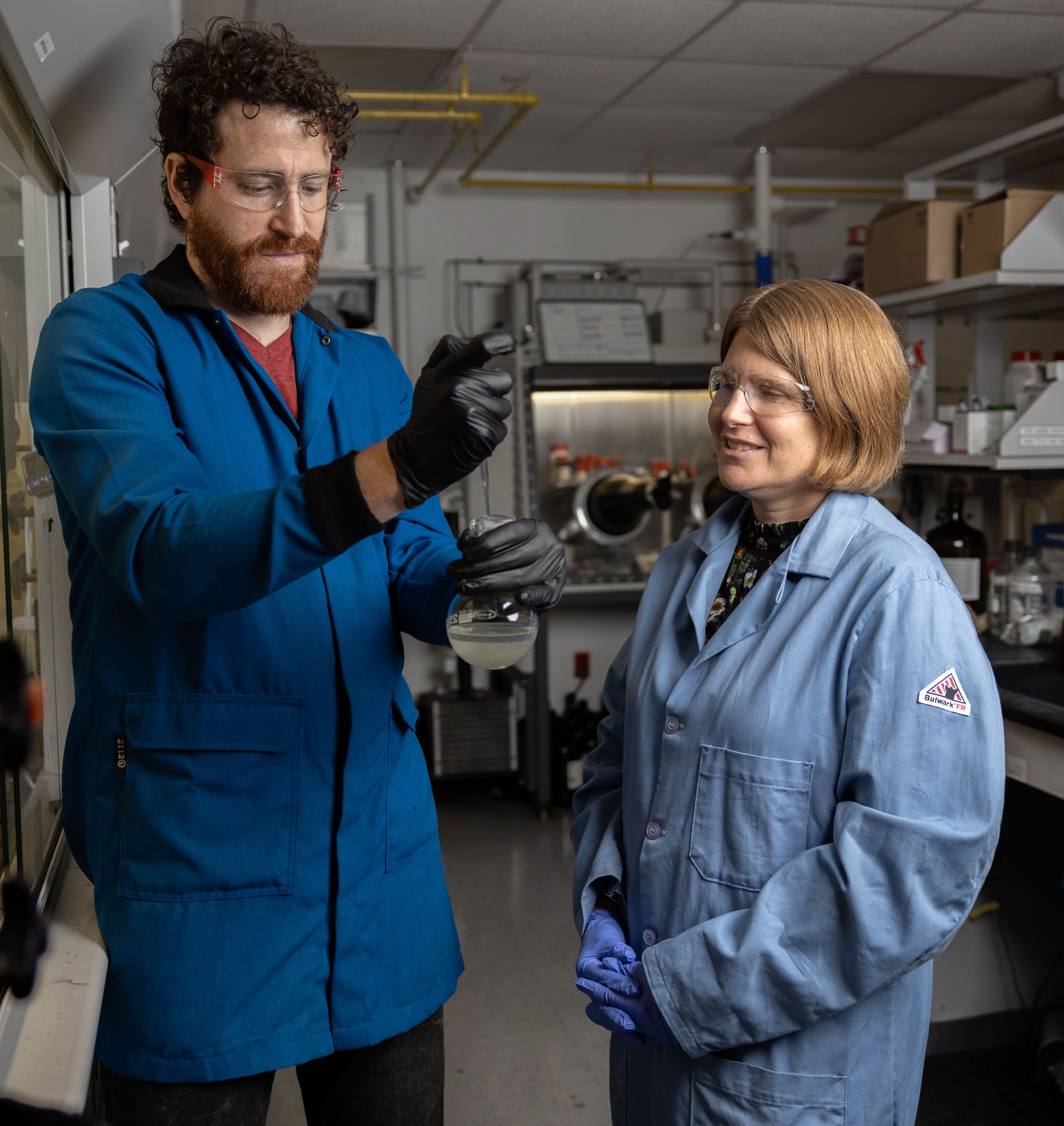

The second focus of their research is on upcycling: converting single-use plastic waste into long-lasting, value-added products, thus extending their lifespan outside of landfills. To do this, Robertson’s team is working to convert plastics into thermosets, particularly polyurethanes used in insulating foams, coatings, furniture and infrastructure materials.

“What we’re trying to do is make the plastic more functional by running it through a commercially relevant process involving extrusion that turns the plastic into a thermoset. This type of thermoset is used for durable products that have a longer life and greater consumer value than the types of plastics used for food packaging, as an example, which end up in landfills much faster,” Robertson said.

A more recent approach, called chemical recycling, breaks the plastics down into monomers (the building blocks of polymers), which can then be used to make the polymers again. This is a circular process, as the same polymer can be broken and reformed many times over. Because polyolefins are highly stable, they are very energy-intensive to break down chemically, which, as Robertson noted, makes it difficult to apply chemical recycling processes to these types of polymers.

Their plan is to create degradable polyolefins that retain their original qualities and functionality, but that can be recycled and reused through this chemical recycling approach.

“Think of it like a loop: instead of making plastic, using it and then trashing it, instead we can create a circular economy aimed to keep the same plastic in circulation for as long as possible while simultaneously retaining its value and avoiding chemical leakage into the environment,” Robertson said.

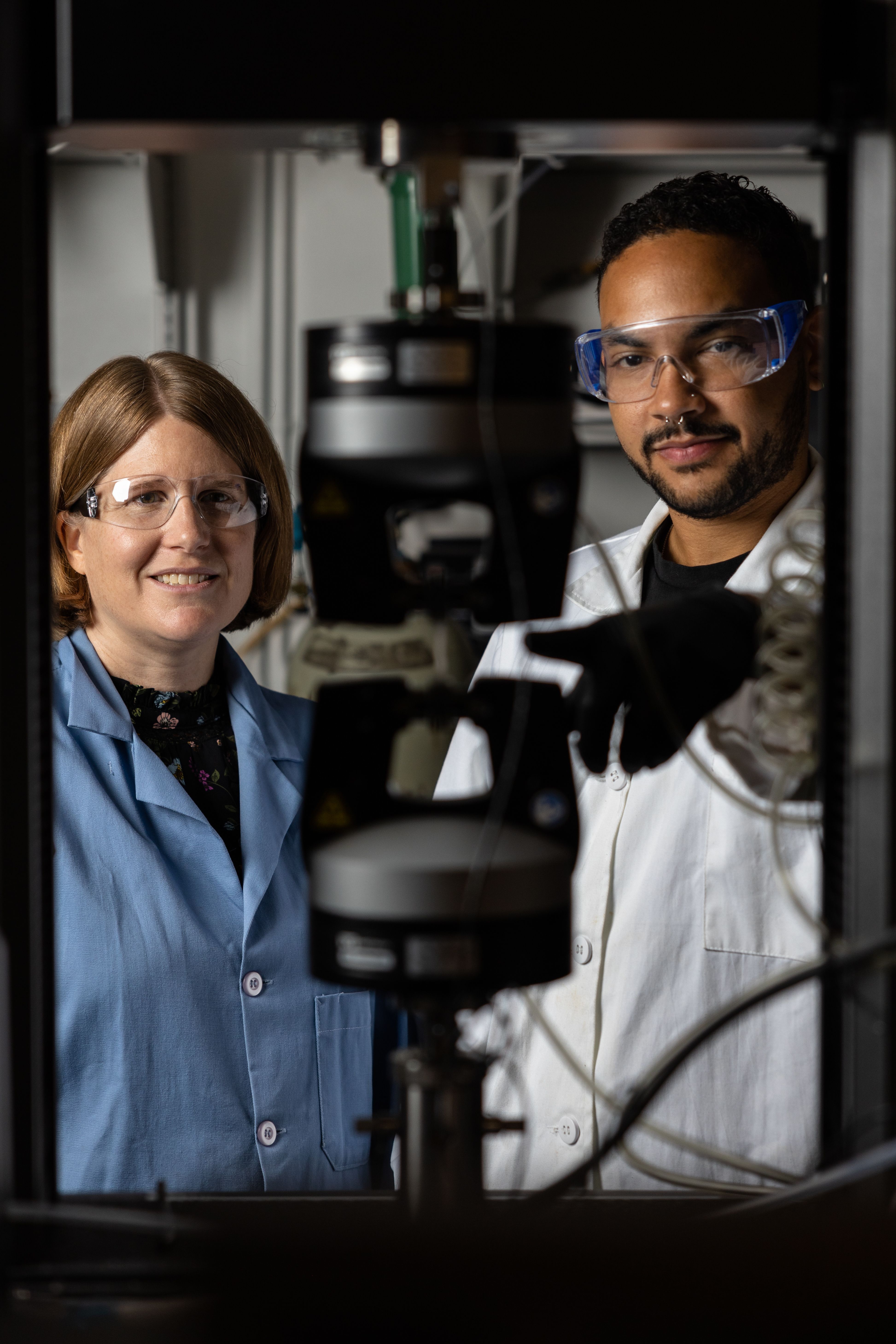

Professor Megan Robertson with graduate student

Professor Megan Robertson with graduate student

“What we’re trying to do is make the plastic more functional by running it through a commercially relevant process involving extrusion that turns the plastic into a thermoset. This type of thermoset is used for durable products that have a longer life and greater consumer value than the types of plastics used for food packaging, as an example, which end up in landfills much faster."

- Professor Megan Robertson

Student-Led Innovations: Addressing Microplastic Pollution

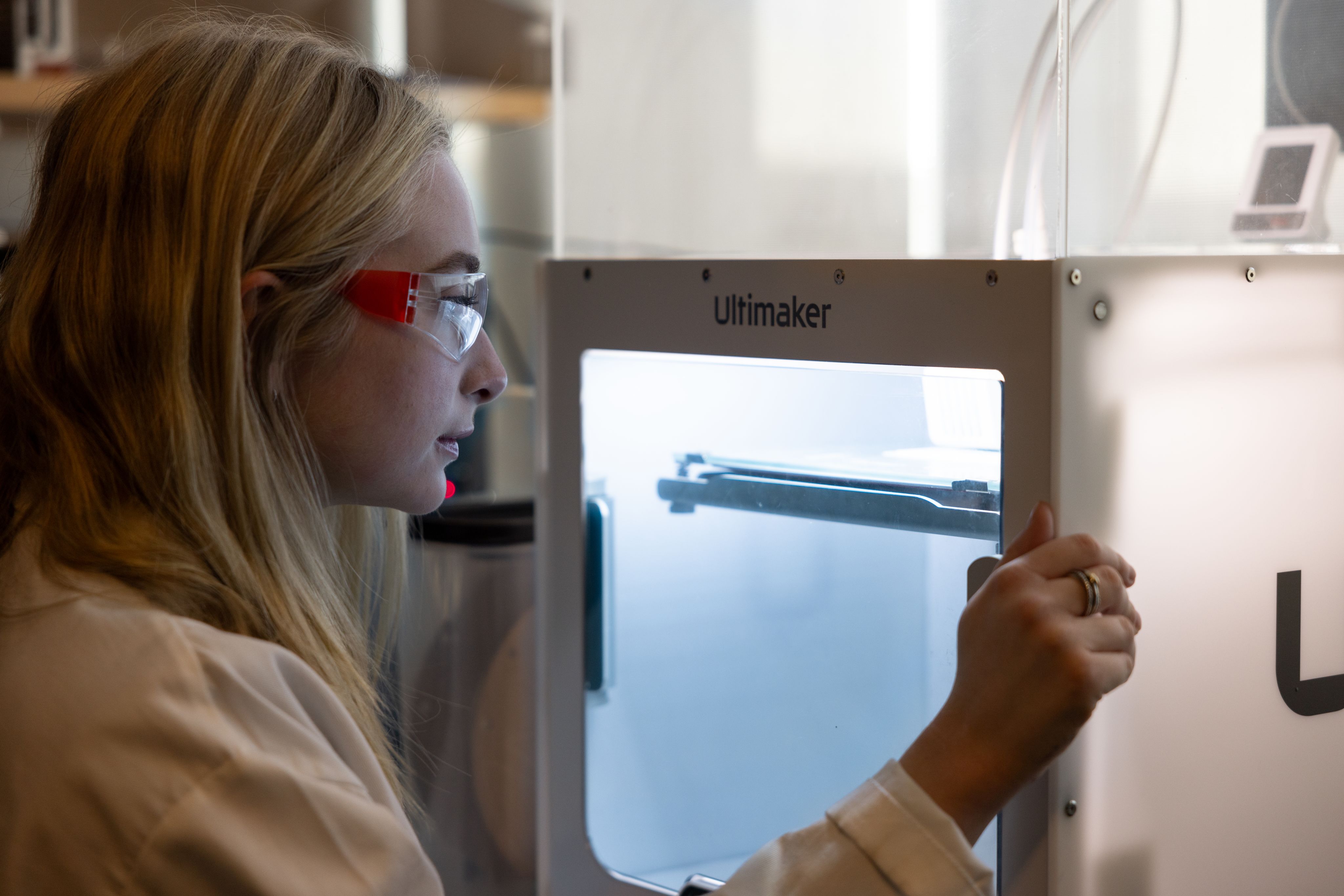

Complementing these efforts are UH students like Sarah Grace Kimberly and Emma Nicholas from the C. T. Bauer College of Business, whose keen awareness and ingenuity are driving innovative solutions to combat plastic pollution.

Last fall, the University’s Energy Transition Institute (ETI) challenged students to develop sustainable solutions for a circular plastics economy: A system by which plastic is responsibly reused so it does not leak into the natural environment.

More than 60 students participated in the inaugural Circular Plastics Challenge and six teams emerged to present their ideas. Each proposal exemplified a knack for creative problem-solving that has become synonymous with the University.

Emma Nicholas

Emma Nicholas

Among the diverse proposals were ideas for limiting excess packaging and replacing plastic products with more sustainable materials. But one stood out. Sarah Grace Kimberly and Emma Nicholas tackled a nefarious byproduct of the plastic crisis: the prevalence of microplastics in personal care products, like makeup. They proposed using a liquid-based membrane functioning like a magnet to capture these tiny, indiscernible plastics that go down our household drains every day.

Their goal is ambitious but vital to significantly reduce the 5.4 million metric tons of microplastics that enter the natural world each year.

“We wanted to provide a simple solution to a growing problem,” says Kimberly, who believes the product could stop pollution at the source. “Before we did this project, we didn’t know that microplastics existed, let alone in our makeup. I didn’t know I was basically putting plastic on my face every single day and washing it off into our drains. Because it’s an unseen problem, it’s hard to address.”

Joe Powell, founding executive director of the Energy Transition Institute, was inspired by what the future could look like with UH students using their skills and intellect to improve the world.

“If you look at the wide variety of proposals and approaches, you can see the complexity of the problem and all the different things that society must consider to find solutions,” he said. “I think circularity in plastics and chemicals is as difficult to address as the net-zero issue within the energy sector, if not more. We have a unique opportunity here to tackle both, and it’s really great to see our students thinking ahead.”

With faculty and students alike at the forefront of this battle against plastic pollution, UH is not only pioneering novel technologies but also nurturing a generation of leaders equipped to confront the complex environmental issues of our time.

"Enabling Polyolefin Circularity Via Chemical Functionalization, Compatibilization, and Upcycling"

The Welch Foundation Catalyst for Discovery Program

Megan Robertson: Project Director, Professor, UH Cullen College of Engineering

Maurice Brookhart: Professor of Chemistry, UH College of Natural Sciences and Mathematics

Brad Carrow: Co-Investigator, Associate Professor of Chemistry, UH College of Natural Sciences and Mathematics

Olafs Daugulis: Co-Investigator, Robert A. Welch Chair of Chemistry, UH College of Natural Sciences and Mathematics

Alamgir Karim: Co-Investigator, Dow Chair and Welch Foundation Professor, UH Cullen College of Engineering

Ramanan Krishnamoorti: Co-Investigator, Professor of Petroleum Engineering and Professor of Chemistry, UH Cullen College of Engineering