Mission: Microchips

Names of Artemis I Team Members Headed to Space on Microchips Made at University of Houston

On July 20th, 53 years after Neil Armstrong took one small step for man and one giant leap for mankind, NASA announced target launch dates for the Artemis I mission, the agency’s long-awaited first step to returning astronauts to the moon and eventually Mars. Even though there won’t be people onboard the Orion spacecraft when it blasts off later this year, it will carry dozens of tiny tributes created at the University of Houston, to the Artemis team.

Long Chang, a research associate professor in the Cullen College of Engineering and expert at the UH nanofabrication facility, answered the call when NASA was looking for a way to honor the thousands of people contributing to the Artemis I mission.

Long Chang, research associate professor

Long Chang, research associate professor

“NASA wanted microchips with everyone’s name on them,” said Long. “But I had some creative liberties in the design because they didn’t really know what we were capable of.”

The Artemis I Space Launch System and Orion Spacecraft atop the mobile launcher at NASA’s Kennedy Space Center on June 14, 2022 (Courtesy: NASA)

The Artemis I Space Launch System and Orion Spacecraft atop the mobile launcher at NASA’s Kennedy Space Center on June 14, 2022 (Courtesy: NASA)

After considering several options that would satisfy NASA’s requirements, Long proposed a process that combines electron beam lithography and reactive ion etching to engrave the nearly 30,000 names onto each of the 80 microchips.

And he had a little surprise in store for NASA.

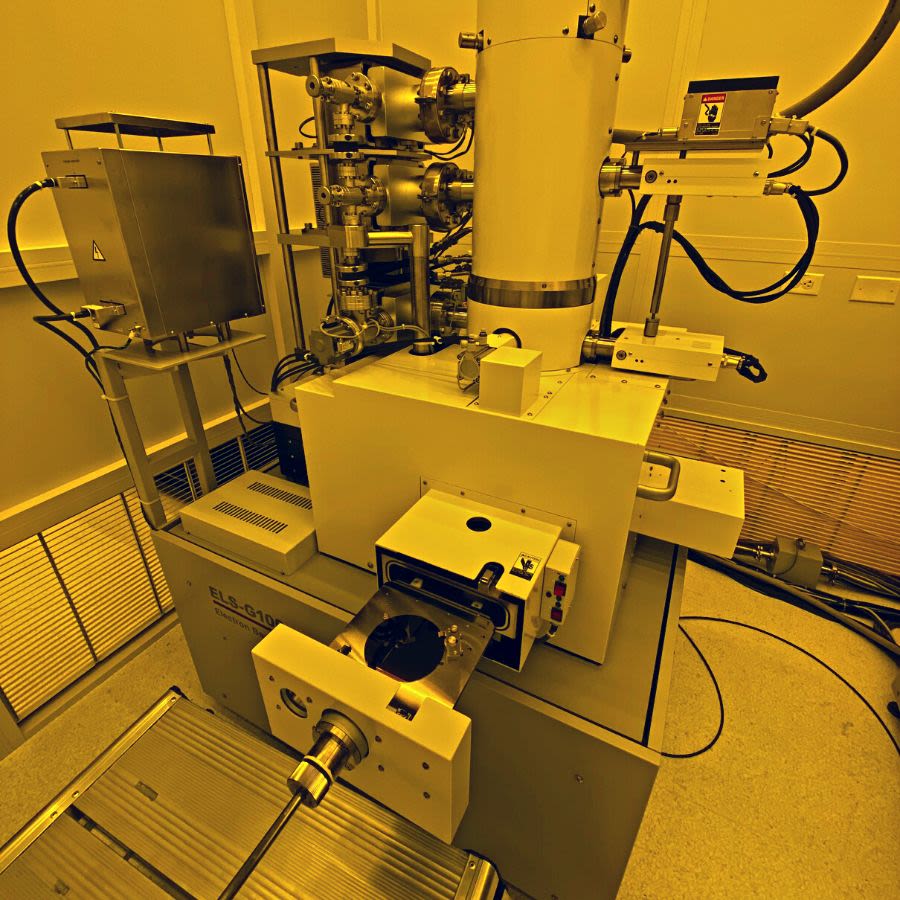

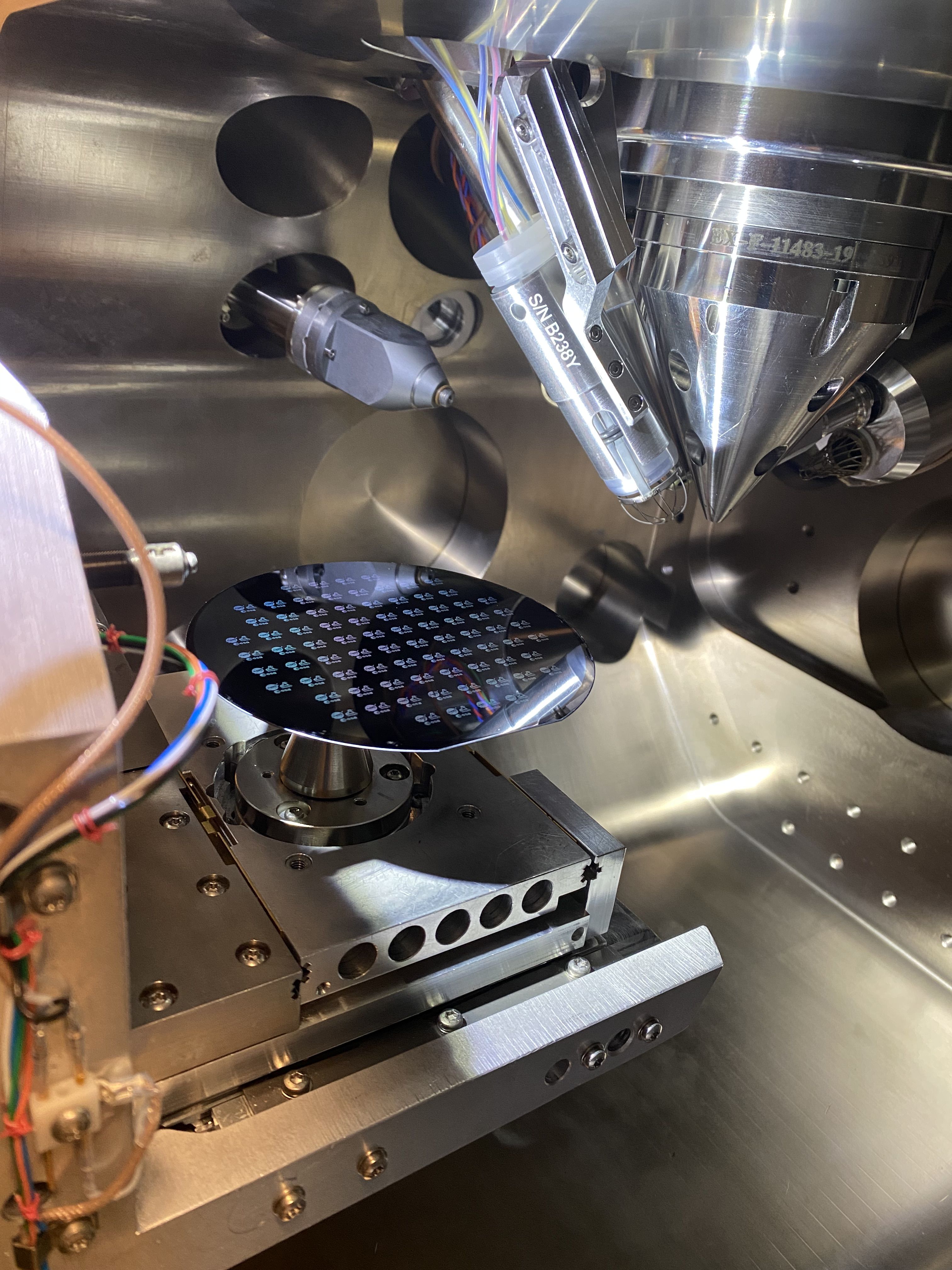

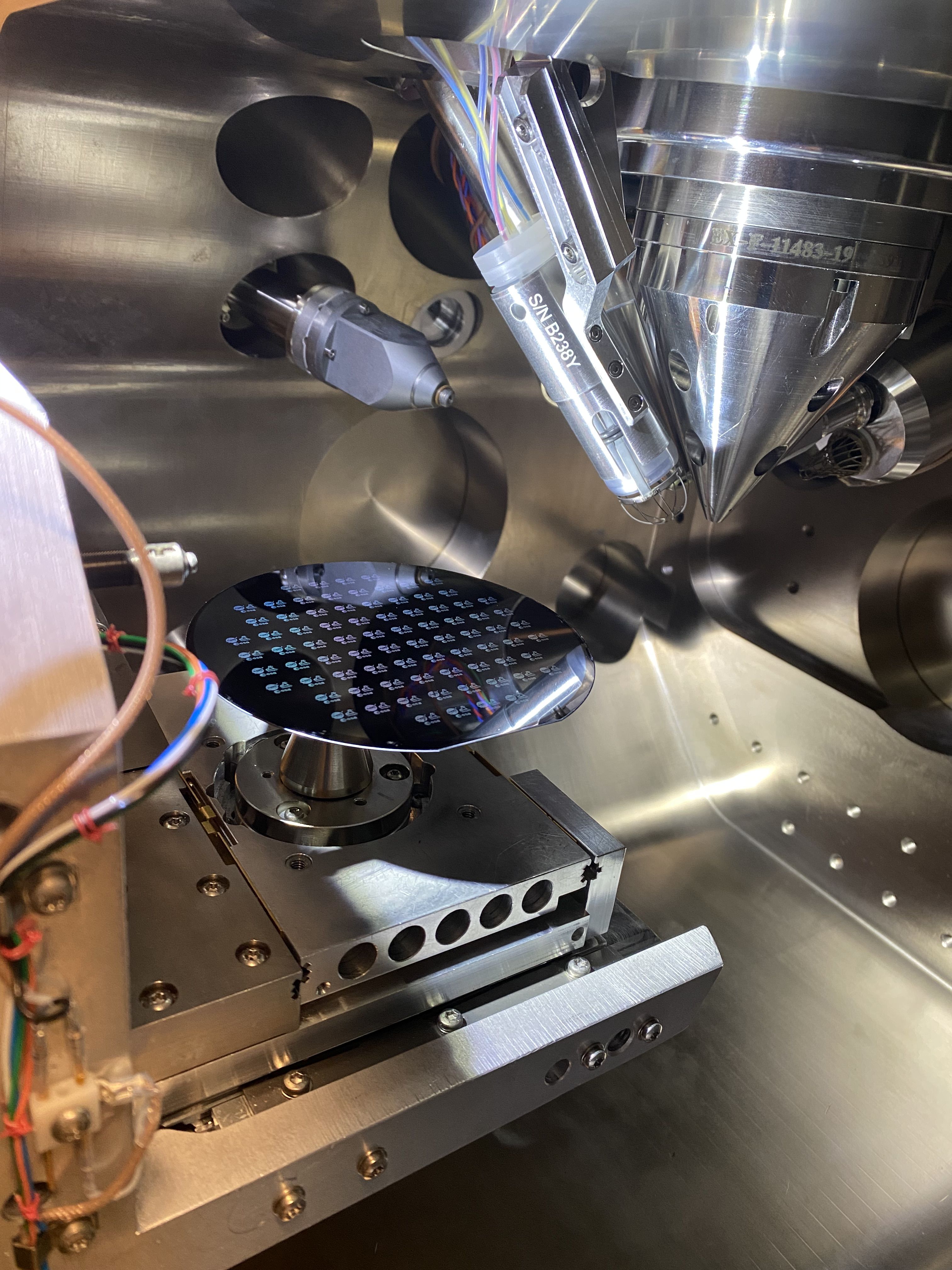

Electron beam writer prints the patterns

Electron beam writer prints the patterns

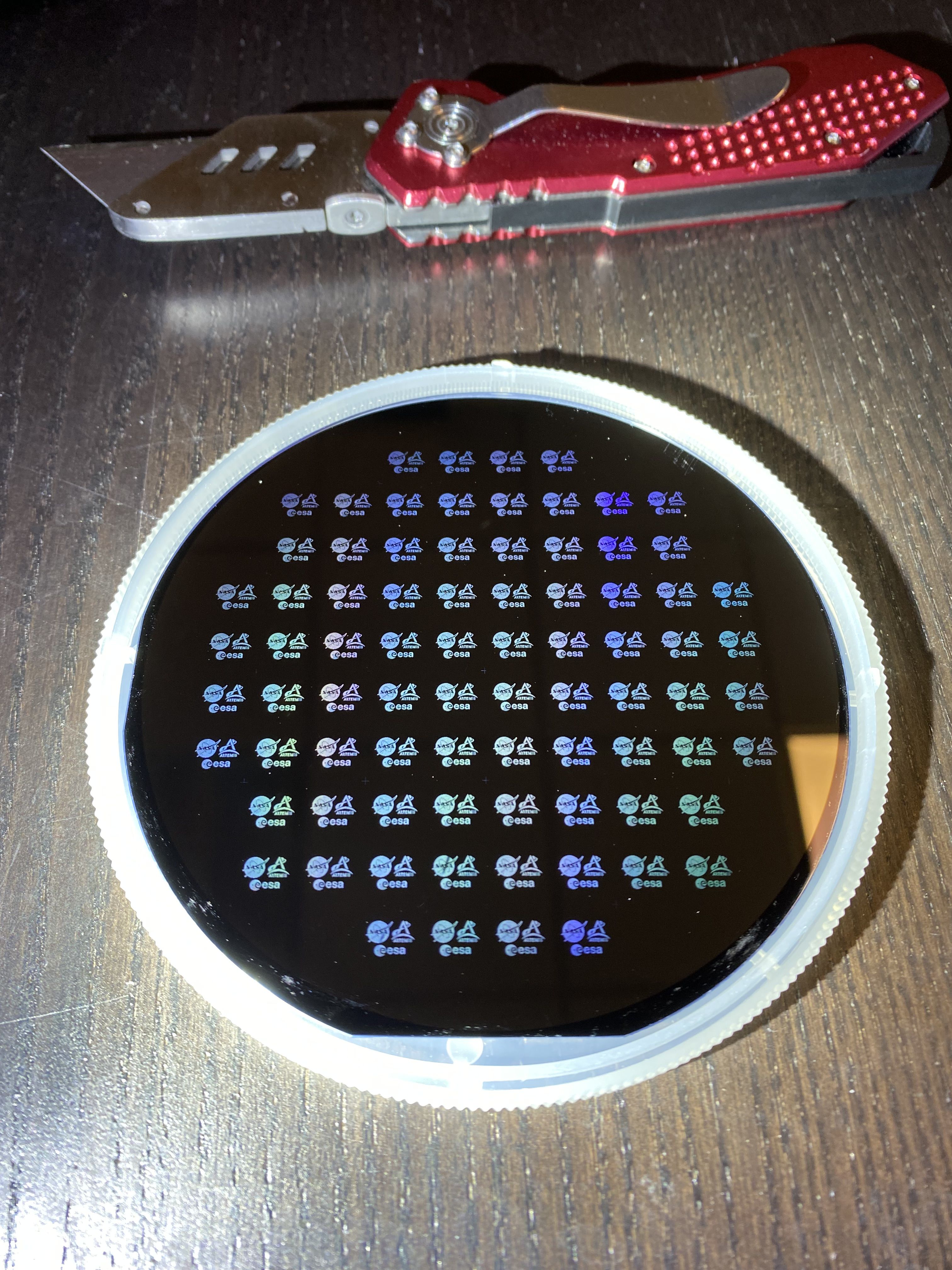

“I figured out how to do this so quickly that I decided to position the names so when you see it, it looks like the NASA logo, the Artemis logo and the European Space Agency logo,” said Long. “Each logo is made of those 30,000 names.”

The names include those from NASA, the ESA, industry partners and suppliers who have contributed to the Artemis program by building hardware, developing systems and supporting mission operations. Similar microchips have flown on other NASA missions as part of outreach campaigns that allowed the public to fly their names in space, including Orion’s Exploration Flight Test-1 and NASA’s Perseverance Mars Rover.

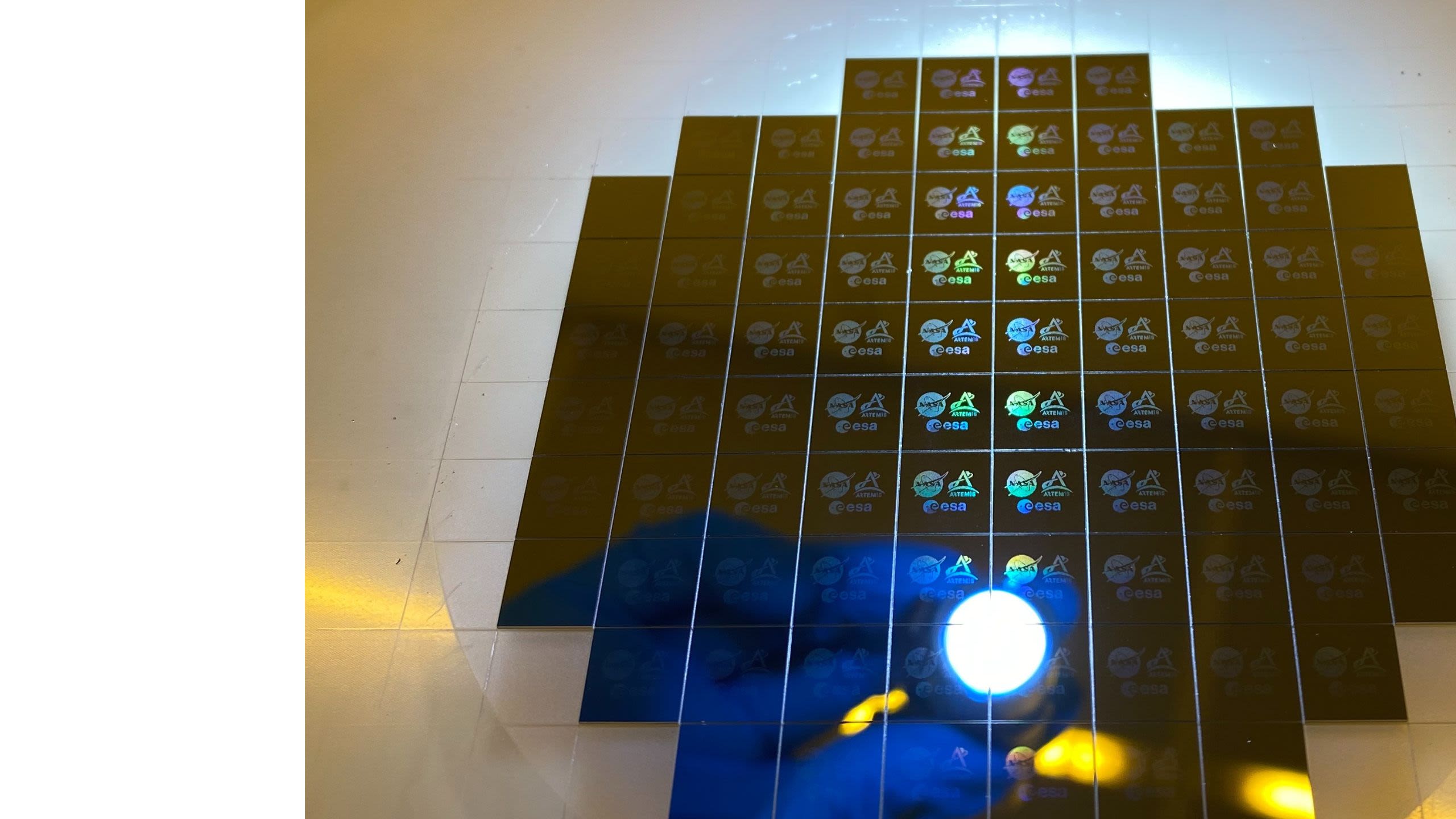

Each logo is made of the names of the Artemis I team members

Each logo is made of the names of the Artemis I team members

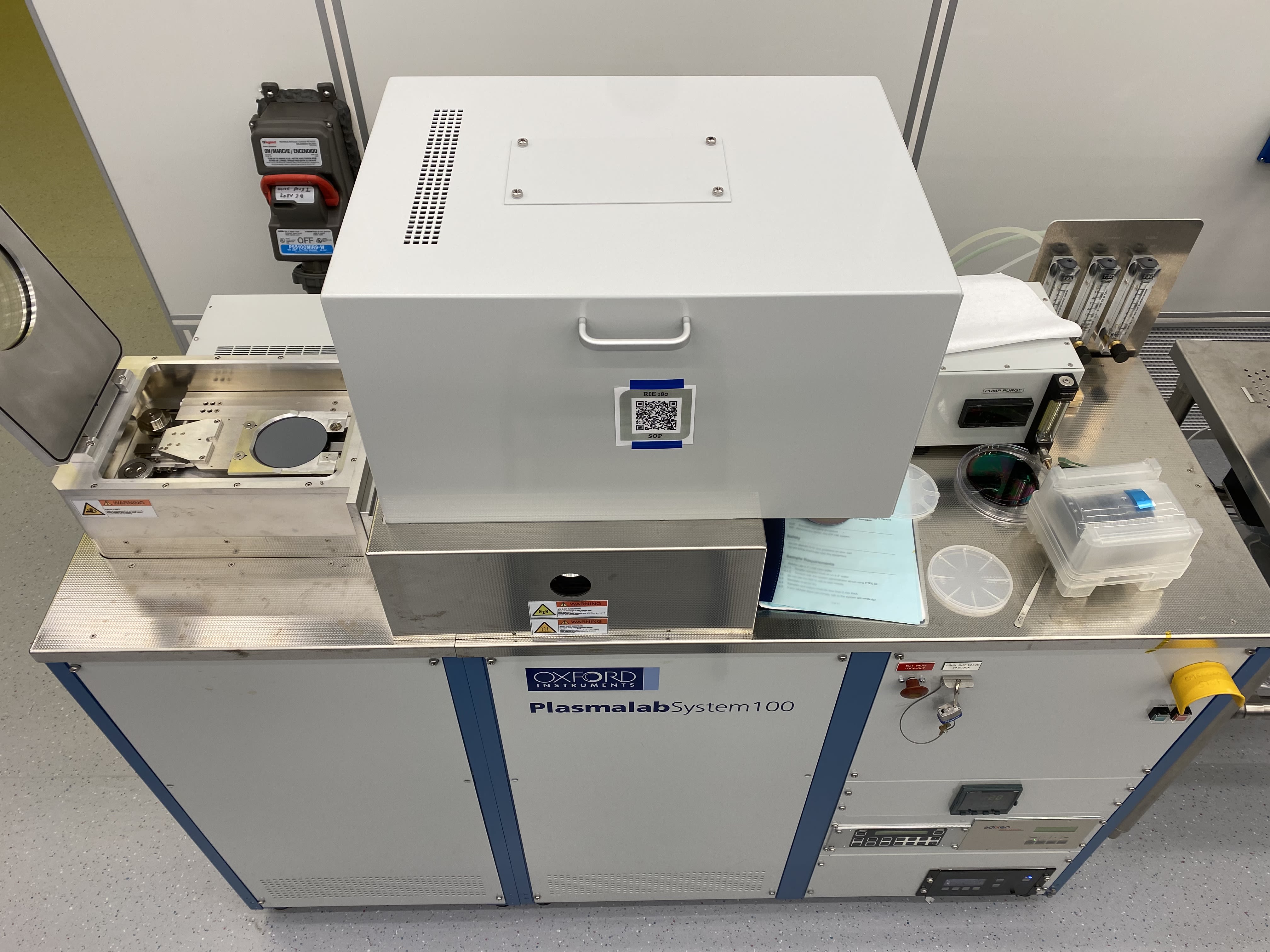

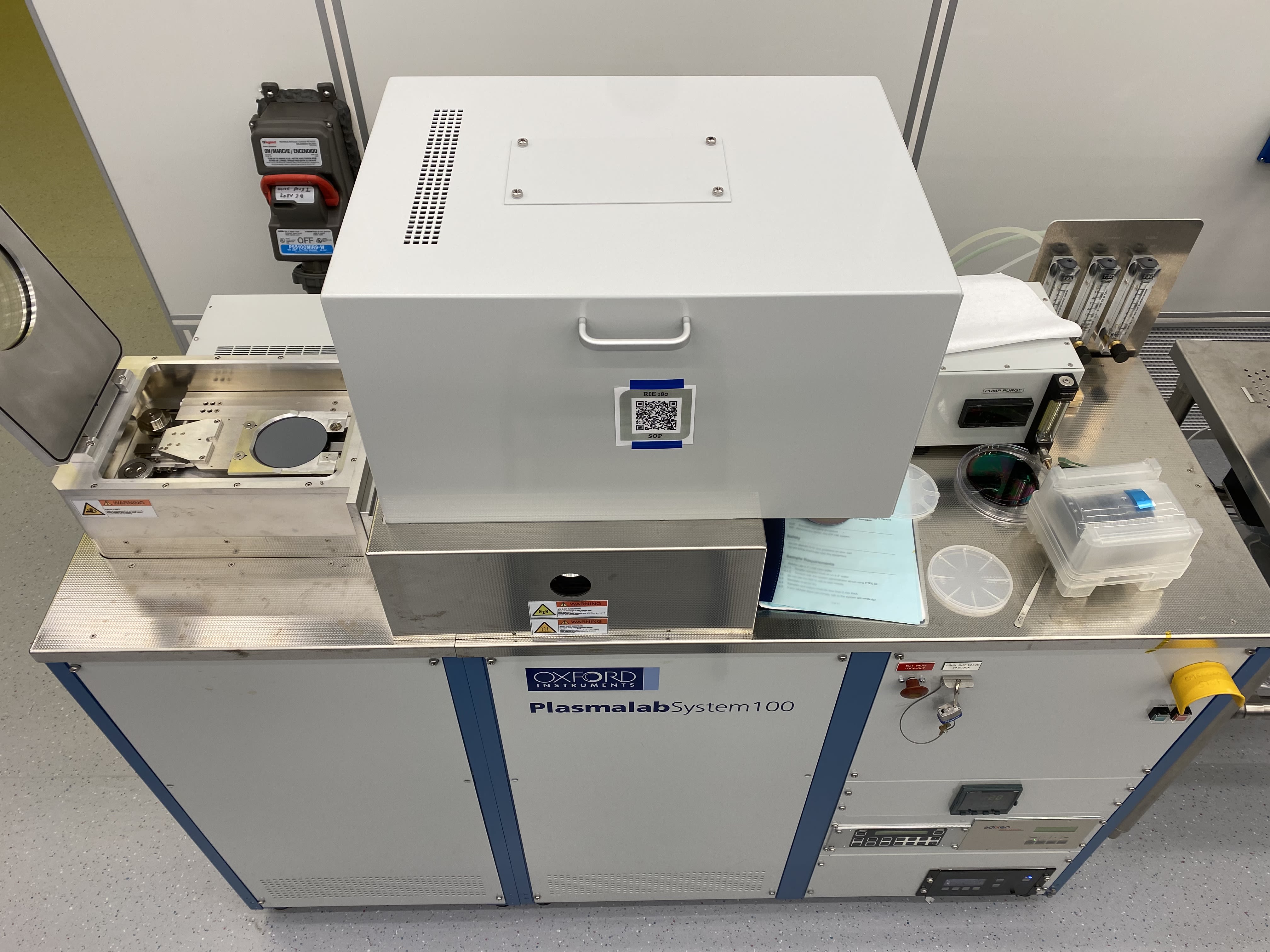

A reactive ion etcher is used to etch the pattern into silicon

A reactive ion etcher is used to etch the pattern into silicon

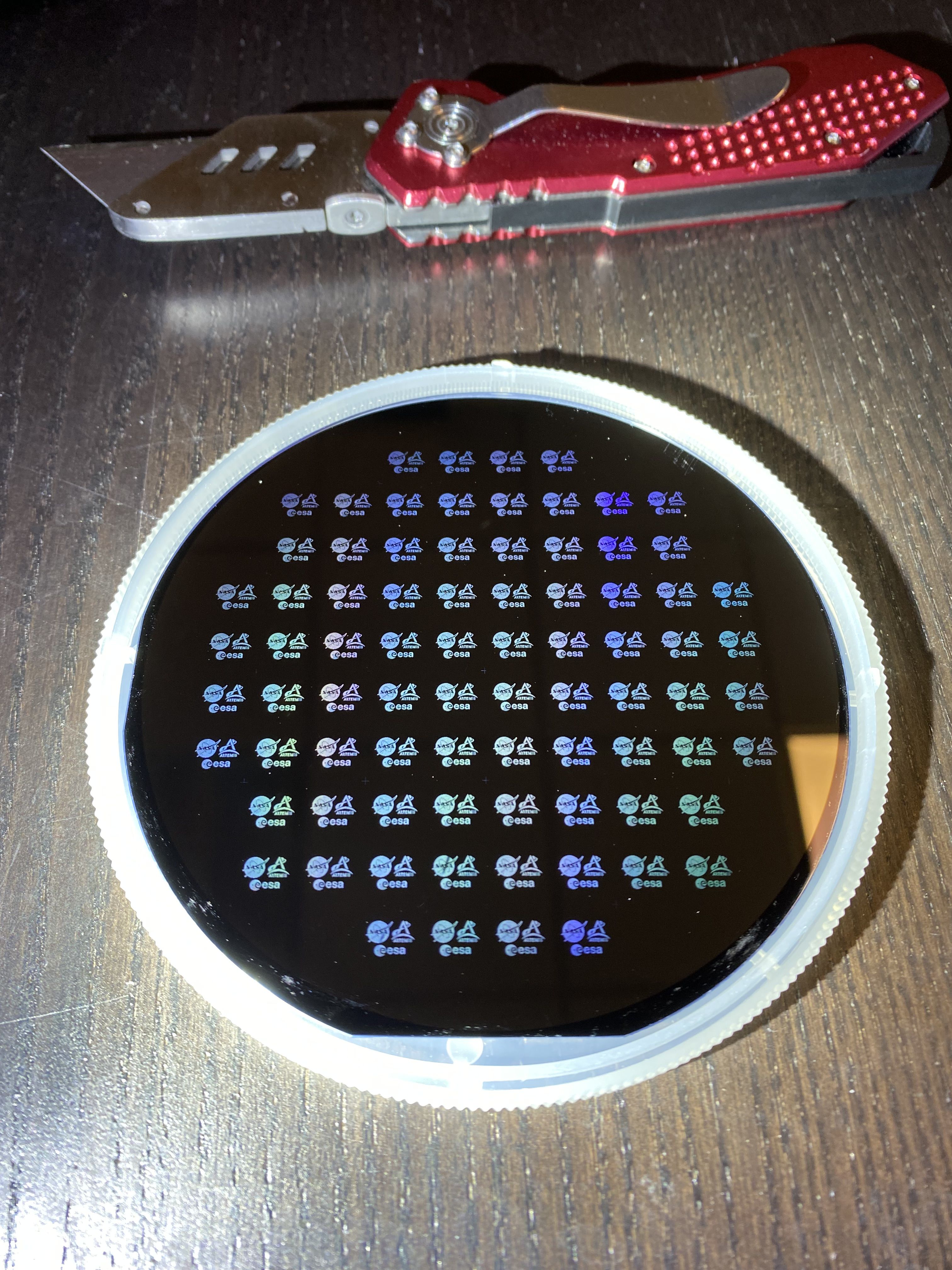

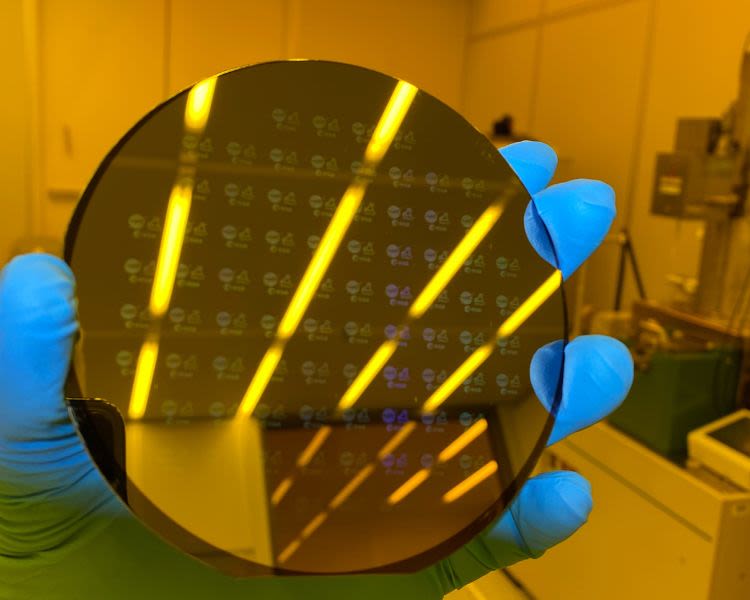

The wafer is diced to produce 80 identical microchips

The wafer is diced to produce 80 identical microchips

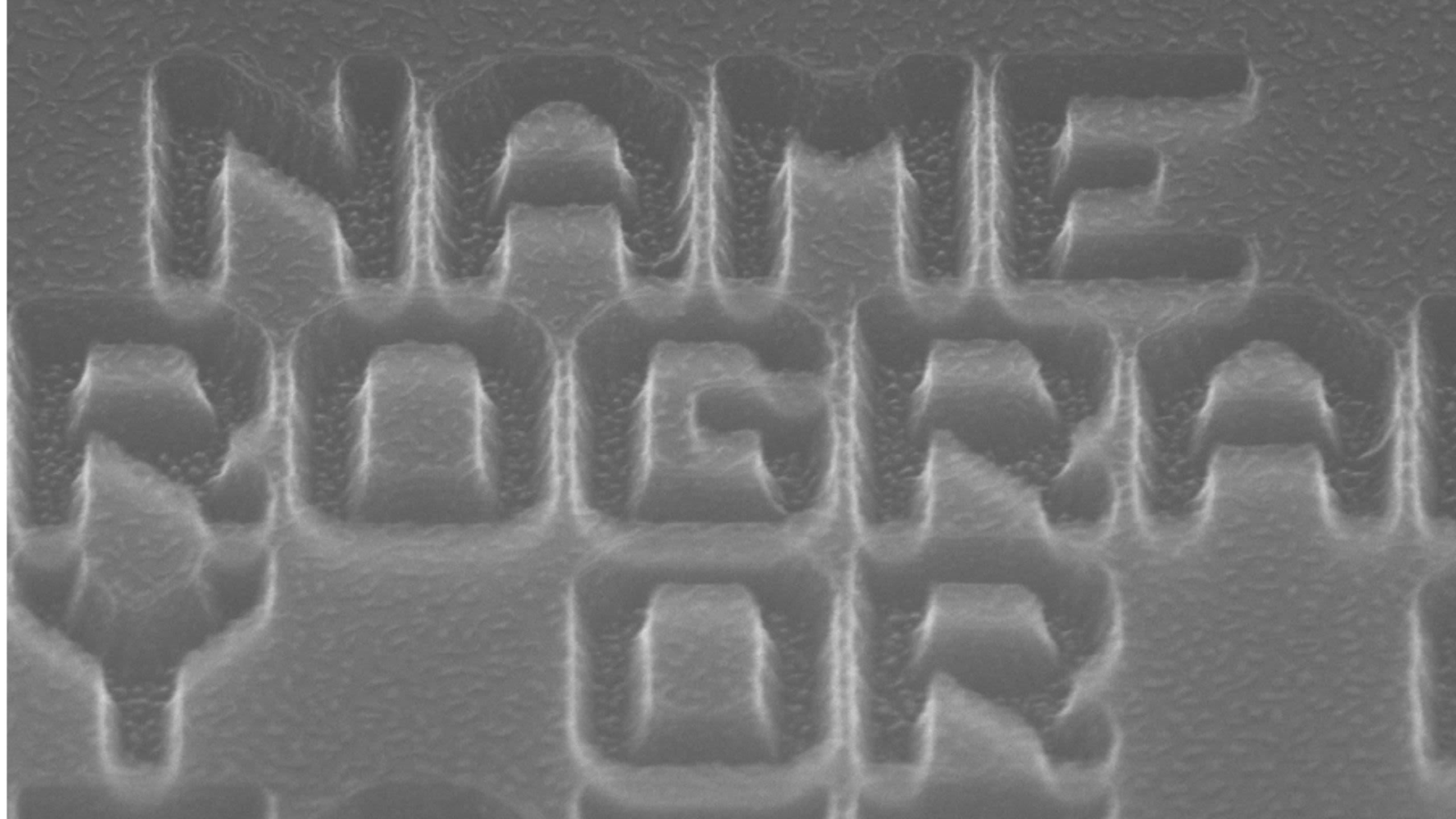

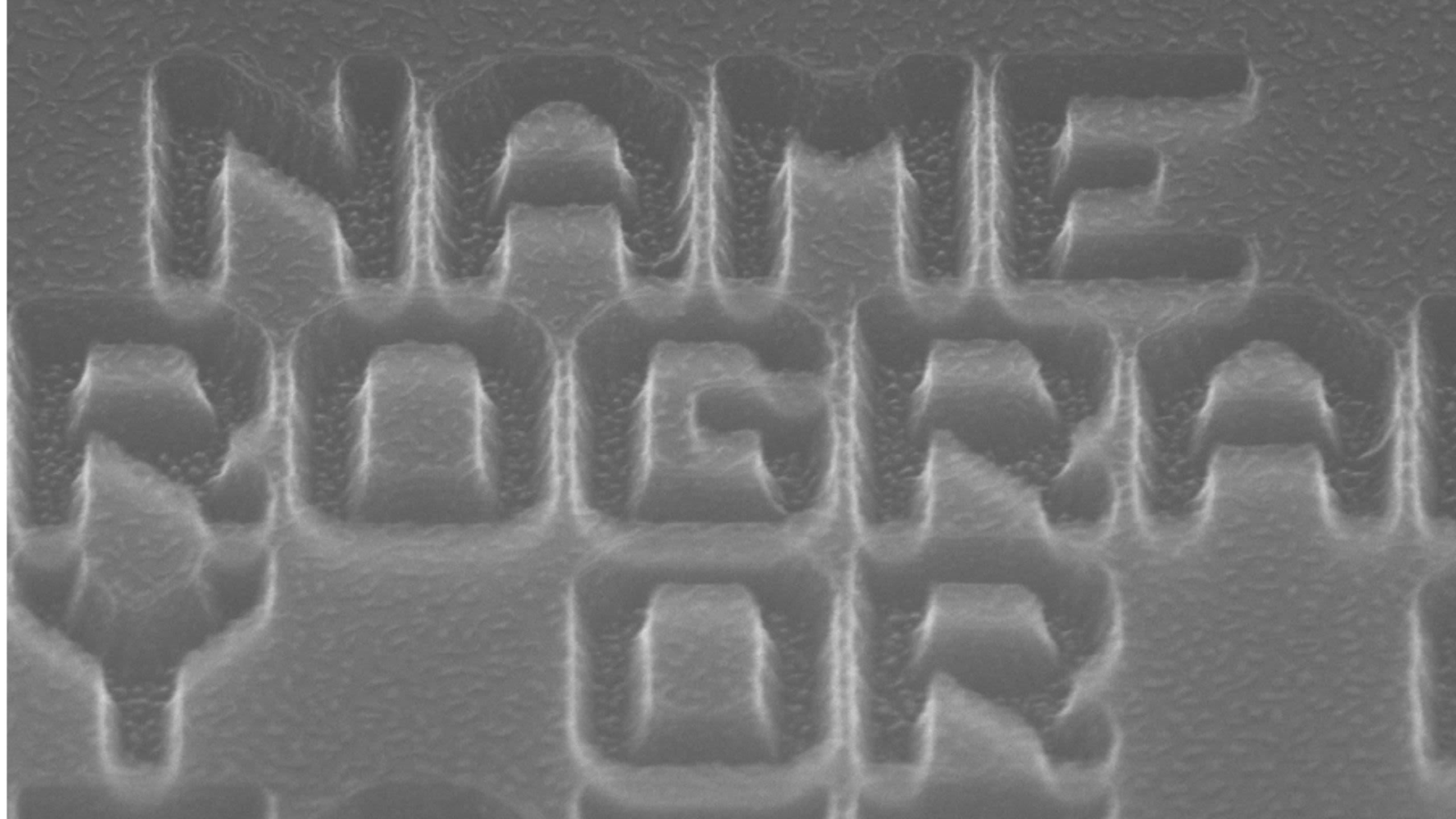

A scanning electron microscope inspects the microchips at up to 1,000,000x magnification

A scanning electron microscope inspects the microchips at up to 1,000,000x magnification

Each letter is 160 nanometers (NM) wide and is engraved 200 NM deep in silicon

Each letter is 160 nanometers (NM) wide and is engraved 200 NM deep in silicon

The 8mm x 8mm microchips will be packed in the Orion capsule’s storage area for its unmanned test flight around the moon. When the spacecraft returns to Earth, the microchips will be given to key program stakeholders in the U.S. and Europe as a memento of the historic mission and an expression of gratitude for all of their hard work.

“By flying our names aboard the maiden Artemis flight to the Moon, a small part of each of us will be flying up there too," said Didier Radola, head of Moon programs at Airbus, the European Space Agency’s lead contractor responsible for building the power system to propel the spacecraft in space.

AMRO Fabricating Corporation in California, which manufactures significant components of Orion’s crew module as well as large structures for the Space Launch System (SLS), is another key partner.

“Our company has been involved in the Orion program from day one, and we are truly honored to see what it has evolved into,” said Mike Riley, CEO of AMRO. “We are really excited to part of this critical and historic piece of hardware that will take humans back to the moon.”

And Indiana-based Major Tool & Machine develops critical components for Orion and for the SLS solid rocket boosters and RS-25 engines.

“The excitement for our customers about NASA’s return to the moon has trickled down to every one of our four hundred employees in Indianapolis,” said Danny Antle, Major Tool & Machine’s vice president of business development. “We’re honored to be a part of the industry team.”

Long hopes this project raises the visibility of the UH nanofabrication facility and brings the world of nanoscale research and engineering to a larger audience. His team of scientists, engineers and technicians provides a wide range of services and support to ensure anyone can use the lab and succeed.

“It’s not just microchips were making here,” Long said. “We have people working on solar cells, sensors for cancer diagnostics, microscopic electronic and mechanical devices, biocompatible materials and superconductor materials. There’s a really wide application for this technology with no limit on the creativity of the person using it.”

- Story published on July 26, 2022

80 identical microchips

80 identical microchips