DOWN TO THE WIRE

The 'Super Cool Conductor' Developed at UH Advances in Prestigious DOE Competition

For more than a century, the conductivity of materials that carry electricity has remained almost unchanged.

For more than a century, the conductivity of materials that carry electricity has remained almost unchanged.

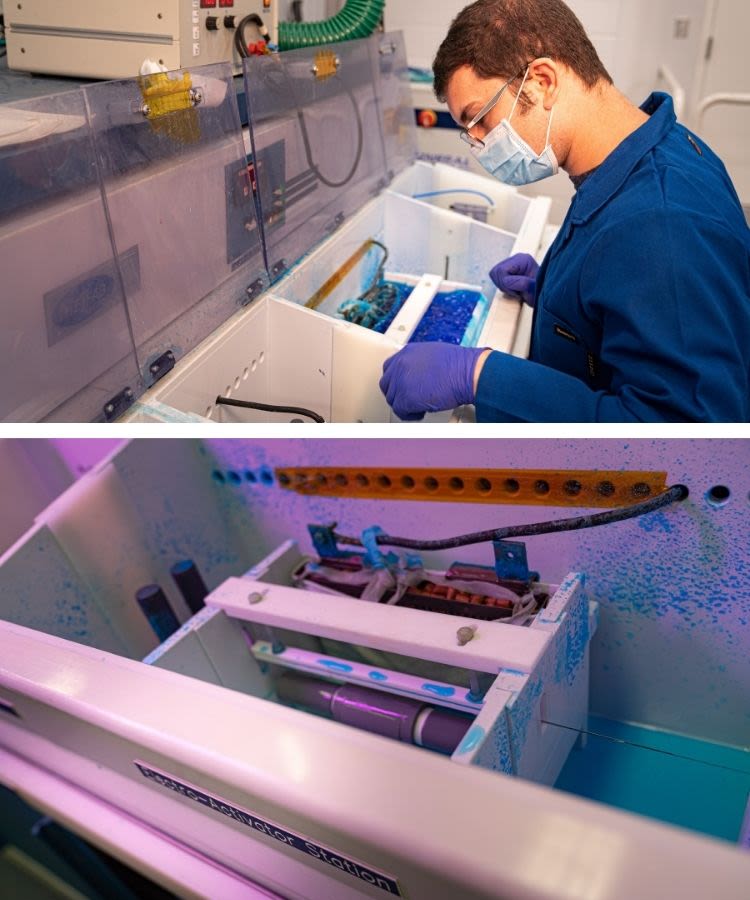

Developing high-temperature superconducting materials for energy applications is an area of expertise for the Selva Research Group.

Developing high-temperature superconducting materials for energy applications is an area of expertise for the Selva Research Group.

Venkat Selvamanickam, M.D. Anderson Chair Professor of Mechanical Engineering

Venkat Selvamanickam, M.D. Anderson Chair Professor of Mechanical Engineering

As the world embarks upon the energy transition, improved electrification will be key to powering an efficient low carbon global economy.

The development of superconductors, materials that can revolutionize the way electricity is generated, transmitted, stored and efficiently used for technologies fundamental to modern life at scale and low cost, will be central to this transition.

The University of Houston is contributing to the energy transition through its research efforts on superconductors.

The Super Cool Conductor from UH’s Selva Research Group was recently one of ten competitors to win the first stage of the U.S. Department of Energy’s prestigious Conductivity-enhanced materials for Affordable, Breakthrough Leapfrog Electric and thermal applications or CABLE Prize. The three-stage competition will award up to $4.5-million to spur development of new materials that enhance conductivity.

Each winning team earned a $25,000 cash prize and a stipend for third-party conductivity testing in the second stage of the competition.

“UH has long been a leader in superconductivity research since the pioneering days of our National Academies member Dr. Paul Chu,” said Amr Elnashai, vice president for research and technology transfer at UH. “Selva’s group is now leading the development of a superconducting wire that is industrially scalable in a cost-efficient manner, which has been the most significant challenge inhibiting widespread applications.”

The DOE CABLE Prize is for researchers and inventors who are working to develop and manufacture breakthrough conductivity-enhanced materials that will speed the U.S. energy and manufacturing industries use of these materials. The conductors must demonstrate "an electric conductivity enhancement an unprecedented seven to eight times larger than that of today’s best copper- and aluminum-based conductors" according to the DOE’s Office of Energy Efficiency and Renewable Energy.

“This is huge for us because we are the only superconductor technology among the ten prize winners at this stage,” said Venkat Selvamanickam, M.D. Anderson Chair Professor of Mechanical Engineering at UH’s Cullen College of Engineering, director of the Advanced Manufacturing Institute and head of the Selva Research Group.

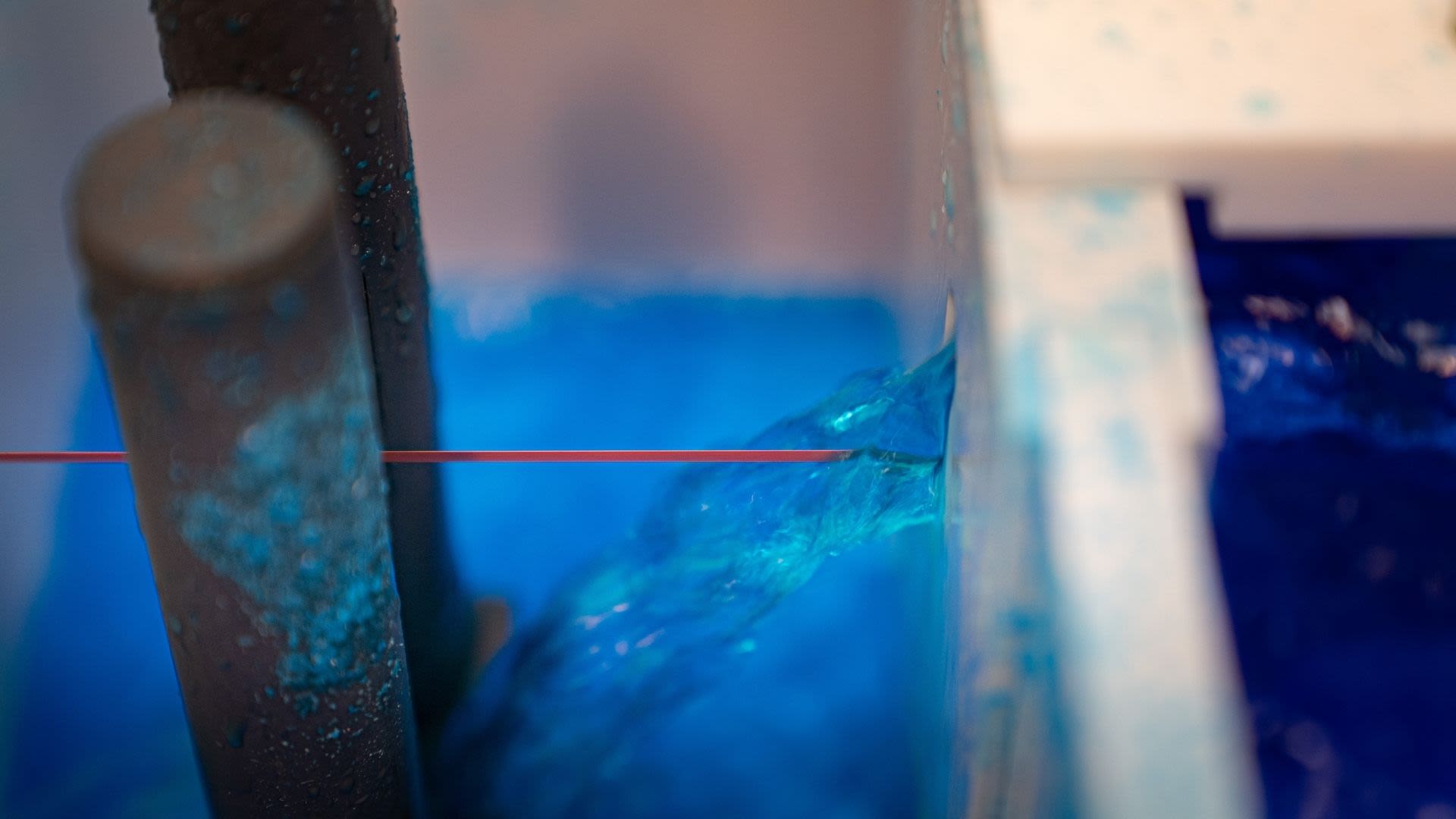

The Super Cool Conductor, a very thin wire which is mostly made of ceramic materials, is a rare-earth, high temperature superconductor that can be manufactured at half the cost of copper and cooled with liquid nitrogen or cryocooling for applications such as long duration energy storage, Selvamanickam said.

Another potential application the Super Cool Conductor could be used for is long-distance power transmission and upgrading copper cables in major metropolitan areas, Selvamanickam added.

Currently, the congested areas of most major U.S. cities bring in power via copper cables from power substations in their region.

If these cables were replaced with the Super Cool Conductor wires, cities could potentially get 10 times the power without having to deal with the associated costs and logistical hassle of digging trenches and installing new copper cables in a city, he noted.

And when it comes adapting to the impacts of climate change, the Super Cool Conductor could be used in places like California that are susceptible to wildfires.

Some of California’s overhead power lines buckled and collapsed and sparked the fires. But if these wires (Super Cool Conductor) were used to replace them and they were buried underground, next to other utilities and natural gas pipelines, it will help solve this problem, he said.

When it comes to renewable energy, Selva Research Group’s wires could be used in wind turbines to generate, distribute and store their power more efficiently.

“They can generate much more power and their impact in transporting the power over long distances from the wind farms to cities could be huge,” Selvamanickam said.

The University of Houston is laser-focused on research that addresses societal problems and improves quality of life, Elnashai said.

“I am therefore delighted to see Selva’s technology recognized nationally and pledge our continued support of the Advanced Manufacturing Institute at UH,” he added.